MIG conical shrouds, also sometimes called tapered shrouds, are funnel-shaped attachments used in MIG (Metal Inert Gas) welding. At Lincweld we offer various conical shrouds in various sizes!

MIG Conical Shroud help shroud the gas around the wire when welding two materials together.

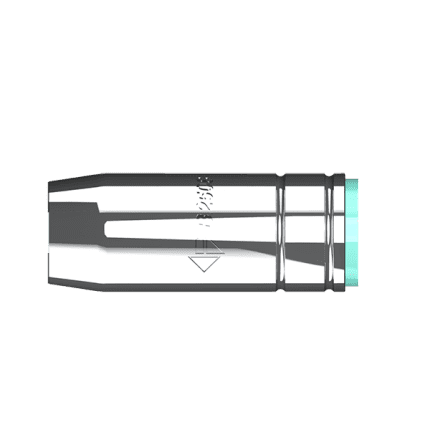

B2508 Cronical Nozzle 15mm 250A (Single)

Frequently Asked Questions:

What are MIG Conical Shroud?

MIG conical shroud are typically made of ceramic or heat-resistant materials and play a vital role in the welding process by:

- Directing shielding gas: The conical shape helps focus the flow of inert gas, like argon or helium, towards the weld pool. This creates a protective atmosphere around the molten metal, preventing contamination from oxygen and nitrogen in the surrounding air. Contamination can lead to weak and brittle welds.

- Improved weld visibility: The tapered design offers a clearer view of the weld puddle compared to a straight shroud. This allows for better control and precision during the welding process.

- Spatter control: The conical shape can help deflect some weld spatter away from the nozzle and the weld zone. Spatter is molten metal droplets ejected during welding that can cause imperfections on the weld surface.

What are the benefits of using MIG conical shrouds?

Here are some of the benefits of using MIG conical shrouds:

- Enhanced weld quality: By providing a more focused gas flow and improved visibility, conical shrouds can contribute to cleaner, stronger welds.

- Reduced rework: Better spatter control can minimize the need for cleaning and rework after welding.

- Improved welder comfort: The clearer view of the weld puddle can enhance welder comfort and control.

Do MIG conical shrouds come in different sizes?

MIG conical shrouds are available in different sizes to accommodate various MIG torch models and welding applications. Some factors to consider when choosing a MIG conical shroud include:

- Torch compatibility: Ensure the shroud has the appropriate thread size and design to fit your specific MIG torch.

- Material thickness: For thicker materials, a larger shroud might be needed to provide adequate gas coverage.

- Welding position: For overhead or awkward welding positions, a longer shroud might offer better gas protection.

Mig Welders

Mig Welders Tig Welder

Tig Welder Stick/MMA Welding Machines

Stick/MMA Welding Machines GYS Plasma Consumables

GYS Plasma Consumables Welder Generators

Welder Generators Sprays/Lubricants & Cutting Fluids

Sprays/Lubricants & Cutting Fluids Welding Helmets

Welding Helmets Helmet Consumables

Helmet Consumables AIR-FED HELMETS

AIR-FED HELMETS